|

|

Quality

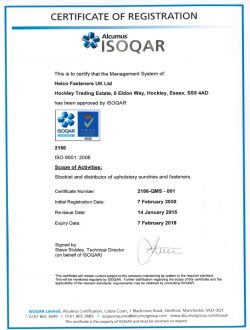

A strategy of continuous process improvements, a constant quest for innovation and a Zero Defect Concept form the basis for our Total Quality Management System (TQMS) and allows us to meet the following quality, performance and environmental standards:

- ISO 9001:2008

- ISO/TS 16949:2009

Our production process is attended by a highly effective quality control system and integrated, dialogue oriented PPS (a quality management tool for production planning and tracking) and BDE (production data acquisition) systems. Both systems provide valuable information to allow a continuous improvement of the competitiveness of our products.

The use of high-quality test devices for series production and the creation of development prototypes safeguard the high quality standard of our products.

In addition to the usual test devices, we offer:

|

|

For many years we have been working with an industry leading ‘Computer Aided Quality’ (CAQ) system. This coupled with the use of ‘Failure Modes and Effects Analysis’ (FMEA) in product development, operations management and production as well as ‘Statistical Process Control’ (SPC) for mass produced parts guarantees quality throughout the manufacturing process.

| Click images to enlarge certificates and print | |||

|

|

|

|

| Home Page | Contact us | © 2014 Heico Fasteners UK Ltd |